Welcome

THE FACTORY

The oil factory Aldobandeschi belonging to the social agricultural co-op is found in Campagnatico, Grosseto on an altitude of 274 metres above sea level. It is about 25km from the region’s capital and it lies on the shores of the Ombrone river. The area, which was once governed by the Aldobrandeschi family and then by Siena; the area suffered from wars and robberies. Only during the Gran-Ducal government was it restored and today it is a famous agricultural area characterized by its medieval appearance.

Why choose us?

Since its establishment, the social agricultural co-op holds Alfa Laval equipment with continuous cycles. During the years these machines have constantly been modernized thus increasing their potential. In 2017 new generation Alfa Laval equipment was purchased with the capacity of processing 2,5 tons of olives per hour. This increased working speed in the various olive vines. Today our annual capacity is about 7000 to 8000 tons of olives based on the season. The variety of processed olives are a mainly frantoio, leccino, maurino, pendolino and moraiolo which are typical of this land. Out storage facility, built solely with stainless steel silos, can hold up to 40 tons of oil. This type of material, with a controlled temperature allows to maintain all of the product’s organoleptic qualities without any alterations. Our extra virgin olive oli is currently produced with olives deriving mainly form the Campagnatico region with only a very small percentage coming from surrounding areas. There are absolutely no foreign products used nor are there blends of oils from other EU regions. The bottling equipments is also in stainless steel and allows us to pack both cans and bottles with a maximum capacity of 5 litres, as imposed by EU norms. We also use clean energy thanks to our photovoltaic equipment with a power of 19KWp covering 35% of the power needs. Hot water, needed for the processing, is, in turn, obtained by the use of a gas boiler.

Expert advice

Aliquam in massa luctus, efficitur justo vitae

Cost savings

Aliquam in massa luctus, efficitur justo vitae

Time efficiency

Aliquam in massa luctus, efficitur justo vitae

Local knowledge

Aliquam in massa luctus, efficitur justo vitae

Local knowledge

Aliquam in massa luctus, efficitur justo vitae

Local knowledge

Aliquam in massa luctus, efficitur justo vitae

Welcome

The equipment

All of our equipment is state of the art thus allowing us to work efficiently and with integrity paying particular attention to environmental issues without having to reduce production capacity.

The mill uses photovoltaic produced energy and a gas boiler for heat.

01

the debrancher

The debranching machine, produced by Mercuri, is in stainless steel and it is used to remove small branches and leaves with a capacity of 4 tons per hour.

02

The washing

The washing machine, produced by Mercuri, is also in stainless steel and it allows to wash about 8 tons of olives per hour.

03

the hopper

The olive hopper, produced by Alfa-Laval, is in stainless steel and holds a capacity of 3 tons per hour.

04

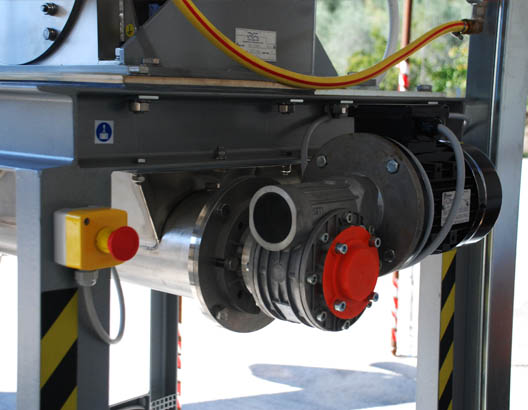

The pressing machine

The pressing machine, produced by Alfa-Laval, is in stainless steel and has a capacity of 3 tons per hour.

05

the malaxer

We have kneading machines holding up to 65lts completely closed and each one can be automatically regulated at an appropriate water temperature for both loading and unloading. These too are produced by Alfa-Laval.

06

the decanter

The steel Decanter X6 BCC is also state of the art and produced by Alfa-Laval. Its capacity is of 2.5 tons and allows saves a great amount of electrical energy as it is equipped with an inverter that produces electrical energy from the machine’s circulatory movement.

07

the separators

N. 2 automatic unloading separators produced by Alfa-Laval.

1200 Q.LI

Annual Production

400 Q.LI

Stored Commodity

25 Q.LI/h

Hourly production

35%

Annual energy saving